DESKTOP INJECTION MOULDING MACHINES

Closing the gap between 3D printing and industrial injection moulding with a fast and low cost solution.

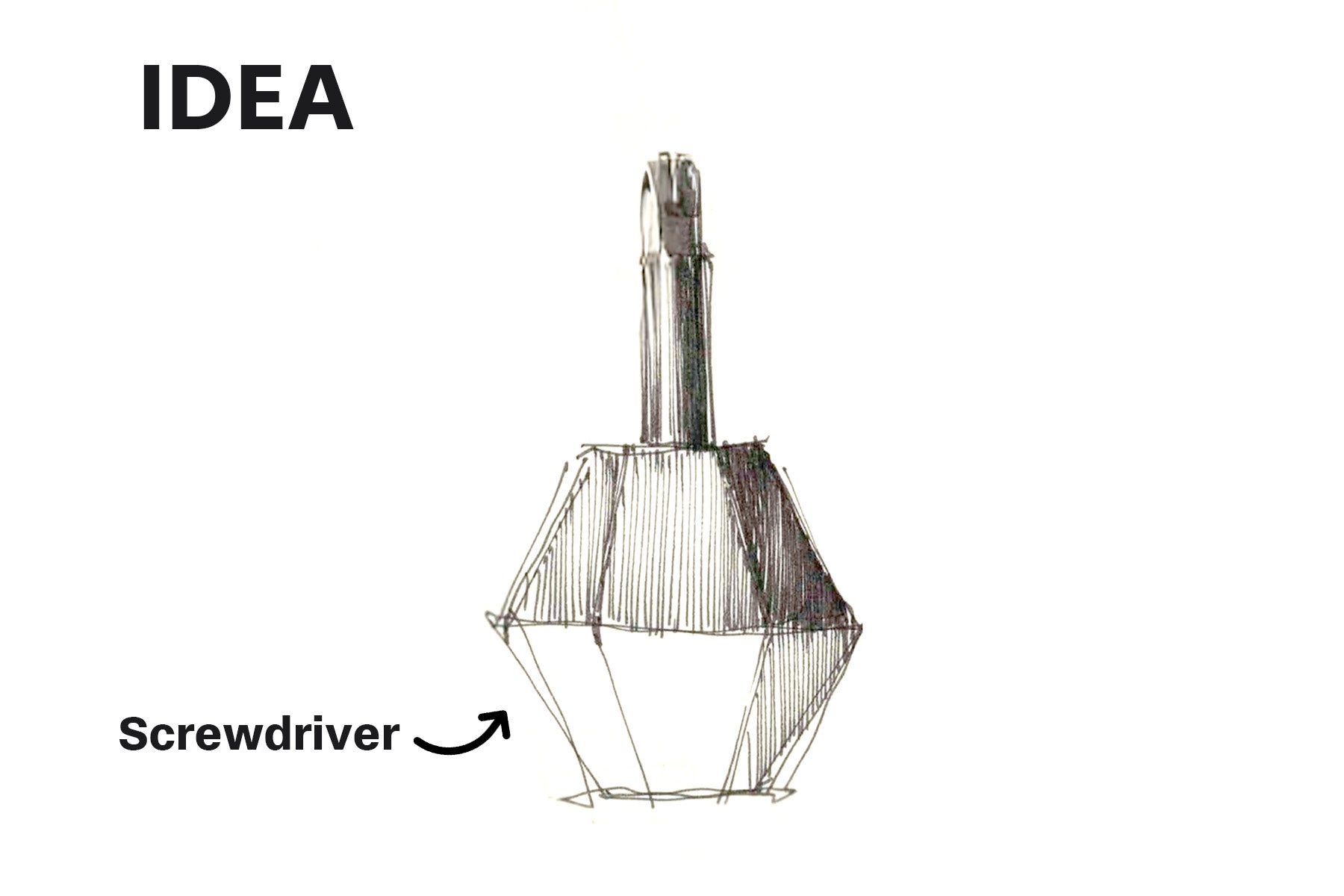

PRODUCT IDEA

3D PRINTED PROTOTYPE

INJECTION MOULDED PRODUCT

BATCH PRODUCTION

INDUSTRIAL PRODUCTION

INJECT THE FUTURE OF PROTOTOYPING

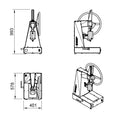

DESKTOP INJECTION MOULDING MACHINES

MACHINE Features

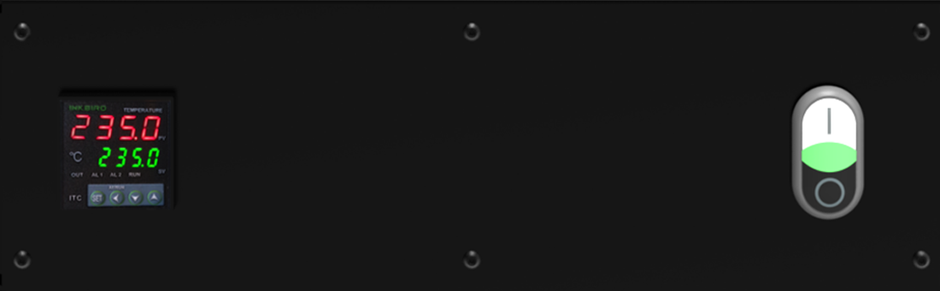

EASY TO OPERATE

SHUT-OFF NOZZLE

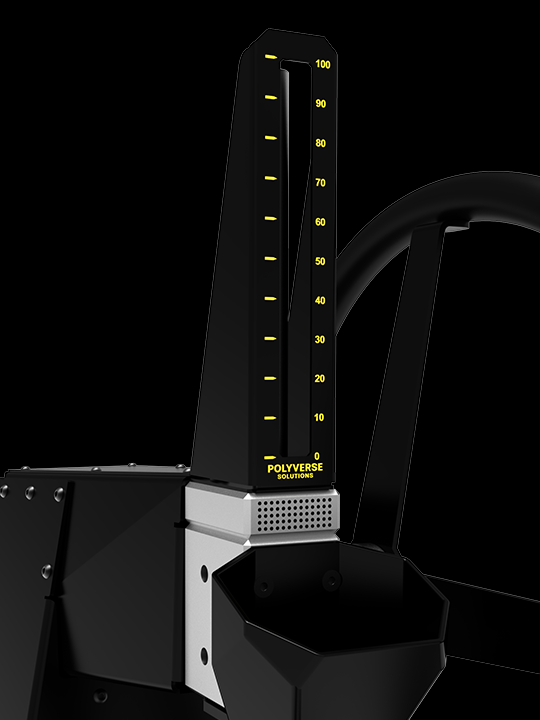

LEVEL INDICATOR

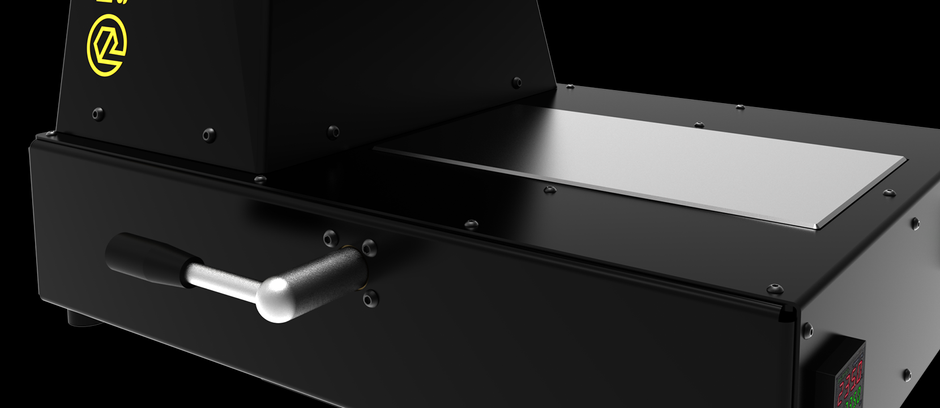

UNIQUE CLAMPING MECHANISM

INTEGRATED FUME EXTRACTOR

WORLDWIDE SHIPPING

with reliable partners

YEARS OF EXPERIENCE

800+ machines delivered since 2020

AFTERSALES

service-team ready to assist

1 year warranty

on all our products

INJECT THE FUTURE OF PROTOTYPING

FAST. SIMPLE. COST-EFFICIENT.

FAST. SIMPLE. COST-EFFICIENT.

FROM IDEA TO PRODUCT

fast iterative prototyping is possible due to the use of 3D printed injection moulds.

FIND OUT MORE

INHOUSE TEST TENSION PRODUCTION

FAST. SIMPLE. COST-EFFICIENT.

FAST. SIMPLE. COST-EFFICIENT.

PRODUCT & MOULD DESIGN SERVICE

Do you need help with your product design? Our team can help bring your injection-moulded product idea to life.

Feel free to contact us with your sketch, technical drawing or 3D file (STEP format preferred).

Either you can then create your own injection mould and manufacture it yourself, or we can take care of this step for you.

Designing injection moulds can be tricky, particularly when multi-part moulds and inlays are required. However, our team will be happy to assist you with every step of the process, from design to production.

We deliver the CNC-milled mould directly to you, ensuring a hassle-free experience.

Need Help?

Here we answer the most common questions about the Polyverse.

If you can't find the answer to your question, please email us.

What materials can be processed with NOVA-60 Desktop Injection Moulding Machine?

What materials can be processed with NOVA-60 Desktop Injection Moulding Machine?

Virtually all thermoplastics can be processed using NOVA-60.

Examples include HDPE, PP, PS and PLA.

Thanks to its maximum processing temperature of 350°C, engineering plastics can also be processed.

e.g. PA and PC.

Flexible materials such as TPU can also be processed.

Is it possible to work with fiber reinfrced materials?

Is it possible to work with fiber reinfrced materials?

Glass fibre and carbon fibre materials can be processed without a problem.

The nozzle will wear out more quickly as a result.

Which materials are recommended for 3D-printed moulds?

Which materials are recommended for 3D-printed moulds?

3D printed molds can be manufactured using both FDM and SLA processes.

For FDM inlays, we recommend PC or PA-CF filament.

For SLA inlays, we recommend Formlabs Ridgit 10k Resin.