Developing plastic injection moulded products in-house means that you are not dependent on external suppliers, which usually incurs high costs and long waiting times.

Furthermore, you no longer need to worry about potentional

data leaks, as all product knowledge remains in-house.

60g SHOT VOLUME

for a wide range of product possibilities

UP TO 350°C

enables the use of a wide range of materials

UP TO 200 BAR

injection pressure for high quality products

ENERGY EFFICIENT

due to custom heating elements and isolation

INTEGRATED FUME EXTRACTOR

for a safe operation and a clean working enviroment

SHUT-OFF NOZZLE

prevents high MFR plastics from leaking out of the nozzle

SPECIFICATIONS

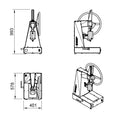

| DIMENSIONS |

| WEIGHT XS |

| ELECTRIC XS |

| POWER XS |

| CERTIFICATIONS XS |

| DIMENSIONS | 40 X 58 X 99 CM |

| WEIGHT | 42 KG |

| ELECTRIC | 200-240 V 50-60 HZ |

| POWER | 670W 2.9A |

| CERTIFICATIONS | CE & UKCA |

WORLDWIDE SHIPPING

with reliable partners

YEARS OF EXPERIENCE

800+ machines delivered since 2020

AFTERSALES

service-team ready to assist

1 year warranty

on all our products

PRE-ORDER NOW!

Contact our Customer Success Team

- sales@polyverse.solutions

-

+43 676 4538214

-

Monday — Friday, 9am — 5pm ET

Need Help?

Here we answer the most common questions about the Polyverse.

If you can't find the answer to your question, please email us.

What materials can be processed with NOVA-60 Desktop Injection Moulding Machine?

What materials can be processed with NOVA-60 Desktop Injection Moulding Machine?

Virtually all thermoplastics can be processed using NOVA-60.

Examples include HDPE, PP, PS and PLA.

Thanks to its maximum processing temperature of 350°C, engineering plastics can also be processed.

e.g. PA and PC.

Flexible materials such as TPU can also be processed.

Is it possible to work with fiber reinforced materials?

Is it possible to work with fiber reinforced materials?

Glass fibre and carbon fibre materials can be processed without a problem.

The nozzle will wear out more quickly as a result.

Which materials are recommended for 3D-printed moulds?

Which materials are recommended for 3D-printed moulds?

3D printed molds can be manufactured using both FDM and SLA processes.

For FDM inlays, we recommend PC or PA-CF filament.

For SLA inlays, we recommend Formlabs Ridgit 10k Resin.