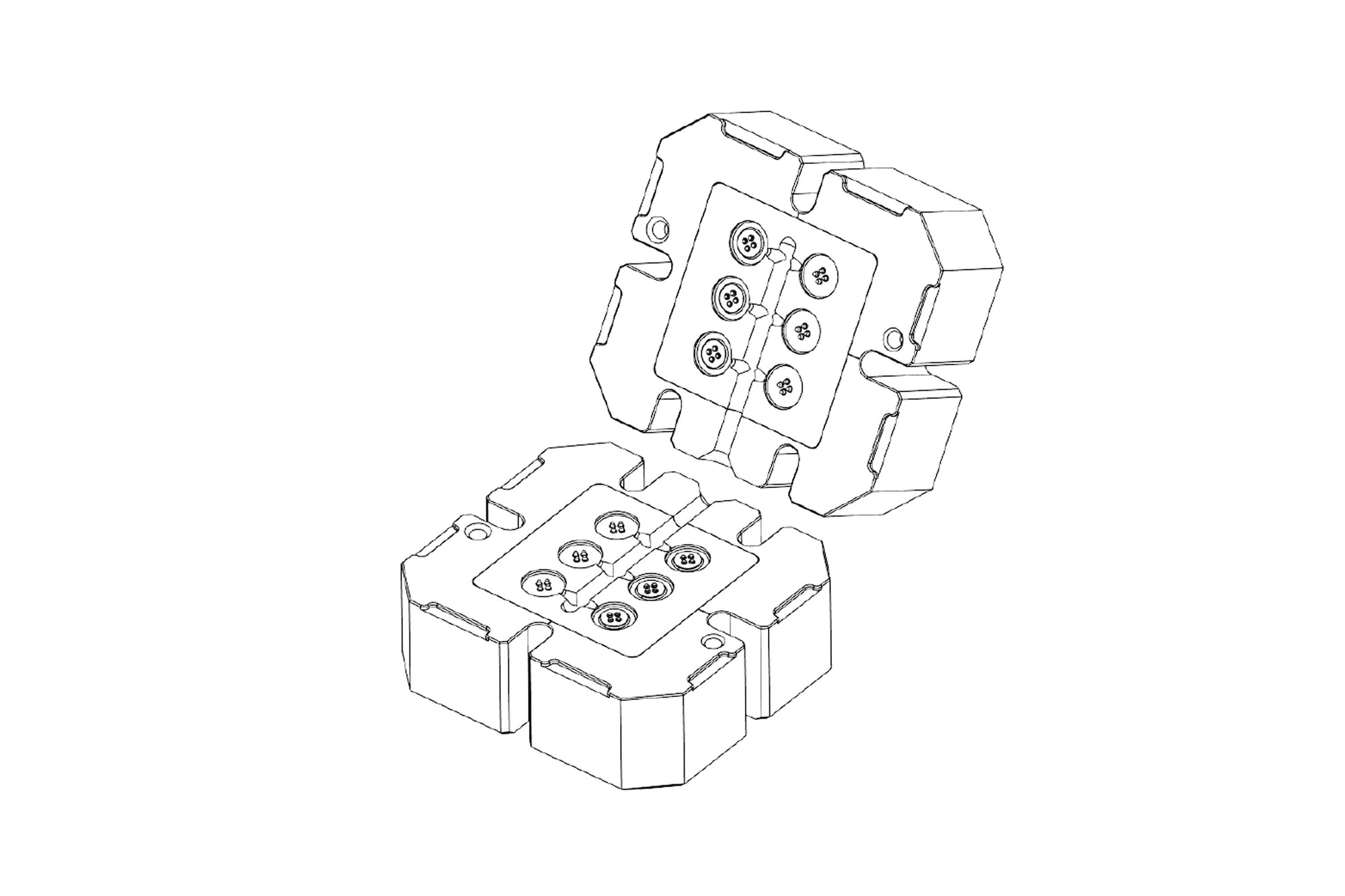

Combining 3D printing with injection moulding opens up exciting possibilities for custom manufacturing. With our Universal Mould, you can harness the best of both worlds: the flexibility of 3D-printed design and the mass-production efficiency of injection moulding. Here’s how it works:

Key Benefits:

-

Customizable and Efficient: The Universal Mould allows you to use 3D-printed inlays, so you can create unique or complex geometries quickly and affordably.

-

Compatibility with Standard Printers: Inlays can be produced on widely available SLA and FDM printers, making this solution accessible to most design and prototyping labs.

-

Durability: Using materials like formlabs Rigid 10K resin, SLA-printed inlays can withstand up to 100 injection shots, ideal for limited production runs or prototypes.

Who Can Benefit:

Perfect for makerspaces, design studios, startups, R&D labs, and Idea2Product spaces, this Universal Mould allows creators to streamline the transition from concept to tangible product.

Easy to Use: Print, clean, insert, and you’re ready to start moulding!

This Universal Mould makes custom manufacturing more accessible and enables rapid iterations for innovative product development.

FDM INLAYS

for simple first design tests to make quick iterations. We recommend using PA-CF or PC Filament

SLA INLAYS

for good surface quality and geometric precision we recommend using Formlabs Ridgit10k Resin

ALUMINIUM INLAYS

for high quality surface finish, geometric precision and long lasting inlays for batch production

SPECIFICATIONS

| SIZE INLAY |

| SIZE MOULD XS |

| WEIGHT MOULD XS |

| MATERIAL XS |

| SIZE INLAY | 70 X 70 X 50 MM |

| SIZE MOULD | 110 X 120 X 80 MM |

| WEIGHT MOULD | 2 KG |

| MATERIAL | 7075 ALUMINIUM |

MOULD DESIGN GUIDE

To give you complete design freedom and independence for your projects, we have created a step by step mould design guide and a 3D base files.

PRE-ORDER NOW!

Contact our Customer Success Team

- sales@polyverse.solutions

-

+43 676 4538214

-

Monday — Friday, 9am — 5pm ET

Need Help?

Here we answer the most common questions about the Roadster. If you can't find the answer to your question, please email us.

How long does a mould last?

How long does a mould last?

As long as the cavity of the mould is not damaged, moulds will last for several years without any problems.

It is recommended to use several moulds of the same type.

It is recommended to use several moulds of the same type.

Yes, definitely. Especially if you have batch production and do not need the entire injection volume for one mould.

Do you also manufacture custom moulds as a service?

Do you also manufacture custom moulds as a service?

Absolutely. To do so, please go to the ‘Services’ tab.